Willie’s Cacao: sofi Award Winning

Willie’s passion for chocolate was born from a love of adventure. This spirit took Willie to Venezuela, leading to the purchase of Hacienda El Tesoro high in the cloud forest, and remains with Willie as the quest to make great chocolate. He has traveled on the cacao trail around the Equator into the forests of the world, in search of the finest beans.

Willie’s chocolate is all about flavor. Great cacaos are like fine wines, each one with its own stunningly individual flavor born of its specific genetics, soil and climate. One might taste naturally of nuts, another of summer fruits. It is to capture these subtle notes and unique flavors that make all Willie’s chocolate from the bean – which is called bean to bar chocolate! The process incorporates buying single estate cacaos direct from the farmers, roasting them in antique ball roasters and make them into chocolate using just raw cane sugar and natural cocoa butter – no soya lecithin, no vanilla, nothing that gets in the way of the flavor of the bean.

Willie’s Philosophy of Chocolate

Willie Harcourt-Cooze’s love for chocolate ignited during his adventures in Venezuela, where he acquired Hacienda El Tesoro and established Britain’s first bean to bar chocolate factory in centuries. He aims to reintroduce the world to the vibrant flavors of real chocolate, crafted from the finest single estate cacaos and 100% natural ingredients. His initial creation was hot chocolate, made with just cacao and sugar, revealing the pure essence of chocolate that has been lost over time. Willie takes pride in sourcing his beans directly from farmers, paying at least $500 a tonne above market value, ensuring fair compensation without intermediaries. Each batch is meticulously produced to showcase the unique flavor profiles of the beans, which are shade grown Trinitario or Criollo genotypes. His dark chocolates consist solely of cacao, raw cane sugar, and natural cocoa butter, without any additives. Willie’s passion is evident as he helps each bean express its distinct flavor, celebrating the journey from bean to bar.

Crafting Excellence

Willie wants to inspire everyone to join his Chocolate Revolution, by sharing his passion for real, artisan chocolate. To do this, he needs to demystify the world of chocolate. So let’s start right at the beginning with ‘How is Chocolate Made?’

Willie makes all of his chocolate the artisan way, from bean to bar, with no short cuts and only the purest of ingredients. So what he’s sharing here, is how REAL chocolate is made.

Willie will tell you all about the almighty differences between artisan chocolate and industrial chocolate another day. But in short, industrial chocolate is made in just a few hours, at high temperatures, using lecithin as an emulsifier, and vanilla to add back some flavor. It is a process designed for cost, whereas the bean to bar process is designed for flavor.

STEP 1

CHECKING THE BEANS

The raw cacao beans arrive at Willie’s factory from the farms in 60kg hessian sacks. The first thing they do is to run some checks. None of their farms use pesticides or chemicals, but it is always good to check there hasn’t been contamination. So all of their beans are sent to external laboratories for testing.

Meanwhile at the factory, they look at moisture content and size variation, and do a cut test to look at the inside of the bean to check how well they have been fermented and dried. There can be no traces of mold that might later affect the flavor of the chocolate. Most importantly, they make a small test batch of chocolate. Is the flavor as pure and distinct as it should be?

When all this is checked, they move into climate-controlled bean storage where they can stay carefree for many years.

STEP 2

ROASTING THE BEANS

A raw cocoa bean doesn’t really taste of chocolate. To develop the wonderfully delicious chocolate flavors, you first roast the beans. At Willie’s factory, he uses the very beautiful, traditional ball roasters, an early 20th century 60 kilo Victor Gruber from Bilbao, and a 250kg 1940’s Bath Sirocco roaster.

This style of roaster is considered particularly good because the beans are swirled around by hot air inside the huge ball. This means they roast evenly and never burn, because they don’t get so broken and don’t touch hot metal.

With artisan chocolate the trick is to evoke and protect the beautiful flavors of the beans.

So he roasts to taste, not to a predetermined programme. For example bigger beans, with more moisture take longer to process. In general, beans this good only need a light roast or their flavors will be dominated by toasted notes. It is a common trick with cheap coffees and chocolates to give beans a heavy roast as this either hides unpleasant flavors, or makes up for the lack of them.

STEP 3

SHELLING THE BEANS

The bit of the bean that they use in making chocolate is called the ‘nib’.

When you break open a cocoa bean, inside the papery shell (the husk) you’ll find these little seed-type nibs. It’s hard to take the shell off an unroasted bean, but once they’re roasted the sheller can gently shake the beans back and forth and the shells rub off and can be separated out from the nibs.

STEP 4

GRINDING AND CONCHING

The cocoa nib is like a small nut and is the building block of chocolate. It has to be refined into a liquid which is called cocoa liquor. This can be done either with granite rollers or with blades in the conching tanks.

Conching is one of the most important parts of the chocolate-making process. The liquor is moved around in a large, heated tank so the unwanted acidic flavors are gradually driven off.

At Willie’s Cacao, they perform this at low temperatures for up to 4 weeks, whereas an industrial maker will do it at high temperatures for just a few hours. Again they do this step of the process to taste, not for a set time.

During this process the particle size gets smaller and smaller, so the liquor gets thicker. To keep the chocolate liquid and flowing industrial makers add the emulsifier lecithin. Artisan chocolate makers add more cocoa butter, which is more expensive but does not affect the flavor.

For Willie, it’s imperative that his artisan chocolate is completely pure so that the varying flavors of the single estate cacaos can truly sing with every bite.

STEP 5

MIXING

What is chocolate? It is cacao that has had other ingredients added to it.

The conched cacao liquor will now have raw cane sugar refined into it to make a dark chocolate. To go on and make a milk chocolate, you would also add milk powder and extra cocoa butter. Then either of those can have further additions like fruit or nuts.

STEP 6

TEMPERING

Up to this point in the chocolate making process, everything is an art. Like a chef you need a feel for it. Tempering chocolate is a science.

Tempering is the process of heating and cooling the chocolate to precise temperatures so that the butter and the solids crystalise together perfectly, before being placed into the mold. This is what creates the beautiful shine on the chocolate, and gives it that everso satisfying ‘snap’ when you bite it. Perfectly tempered chocolate has a super smooth texture and it melts in your mouth in the most wonderful way.

On shows like Masterchef many a contestant has lots vital points for running out of time to temper their chocolate to coat their show stopping dessert! On a small scale in a kitchen most people will use the Seeding Method.

You’ll find it much easier to temper proper couverture chocolate, which is chocolate specially designed for cooking that has a little extra cocoa butter. This keeps it more liquid and easier to handle.

STEP 7

MOLDING, COOLING AND WRAPPING

Finally the tempered chocolate is poured into molds, vibrated to spread it out evenly, then sent through a cooling tunnel so the heat is gradually removed and the chocolate shrinks back so it will pop out of its mold, ready to be wrapped in beautiful packaging.

STEP 8

EATING

Finally the chocolate is ready to be devoured. The exciting and wildly varying flavors of fine single estate cacaos have all been perfectly captured.

Now you are something of a real chocolate expert! This means you can check what kind of chocolate you are eating. Just look for chocolate that contains no lecithin or vanilla. Industrially produced chocolate always use these additives. If it doesn’t have either, then you are about to have the sheer joy of tasting real artisan chocolate, made in the bean to bar process that you have just read about.

Distinctive Flavor Profiles

Rich Dark Chocolate

Exotic Origins

Willie’s Cacao brings out the unique flavor of each cocoa origin, all designed to celebrate the richness of cacao and offer a truly memorable tasting experience.

Exotic Infusions

What Our Customers Say

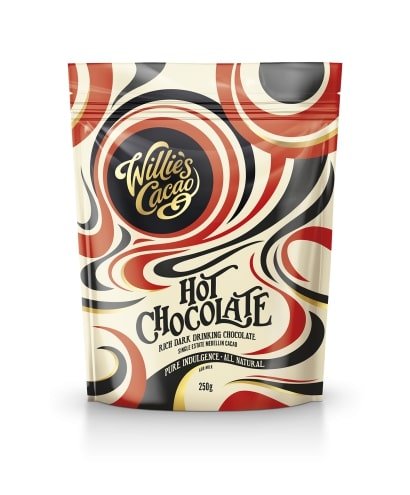

Willie’s Cacao Medellin Colombia Rich Dark Drinking Chocolate

“I’ve been drinking hot chocolate every morning for more than a decade. Many brands are unnoticeable at best, but Willie’s is deep! If it’s too sweet you can adjust with unsweetened grated chocolate—you’ll still taste that creamy chocolatey deliciousness that is Willie’s.”

-ET

Willie’s Cacao Pure Gold Sur Del Lago Venezuela 100% Cacao Bar

“There’s no sugar or sweetness in this chocolate at all, and it is still amazing. Sometimes I eat a piece with a medjool date, and it’s like I’ve been transported. Amazing.”

-ML

Willie’s Cacao Peru 100% Cacao Bar with Raisin & Hazelnut

“Let the mellow, smooth bite of 100% cacao bathe your tongue, and you will be rewarded by the sweet taste of raisin and the crunch of hazelnut. An amazing sensory experience!”

-SS

Willie’s Cacao Peru 100% Cacao Bar with Pistachio & Date

“One of my most favorite brands at its richest and purest. only for the strong of heart- for true connoisseurs who want only most intense chocolate with the best flavor. This perfect darkest dark is enhanced by the diverse texture of pistachio and date.”

-SM